What Is The WHaTS?

The WHaTS is not like most tools. Most tools are just an extension or improvement on an existing tool. Wrenches, saws, grinders and the like keep getting better but they're nothing new. And while the closest comparison to the WHaTS would probably be the wheel barrow, you'll see that it's a thin comparison and is so very much more. So, when we at QHTR find a tool that is something new, it catches our attention, quick.

The WHaTS (Wheeled Hand Tool System) may not be considered a hand tool by tradition, it can't be held in your hand, but one whole point of the system is that it's operated by hand.

With this system, you can...

- Move up to 500lb rocks

- Pull Small Trees, invasive plants, and fence posts

- Move up to 1/8th cord of firewood (or 1200lbs worth of other cargo)

- Carry Plywood

- Move Full size tree trunks and large poles

- Move Trailers

- Convert Quickly into a lawn tractor trailer

- Load and transport full 55 gallon barrels

all without a motor!

Being able to do work without a motor has several advantages…

- In the wake of a hurricane, tornado, earthquake or any other natural or man-made disaster, there is frequently no power to operate machinery and frequently dwindling fuel sources.

- You may live off the grid and have no heavy equipment.

- You may be concerned about the burning of fossil fuels.

- You just may not be able to afford the high cost of equipment to get the work done that you need to do.

The WHaTS could be just the answer for all these situations and more.

Grade:

-Serious Hobbyist-

Initial Impression

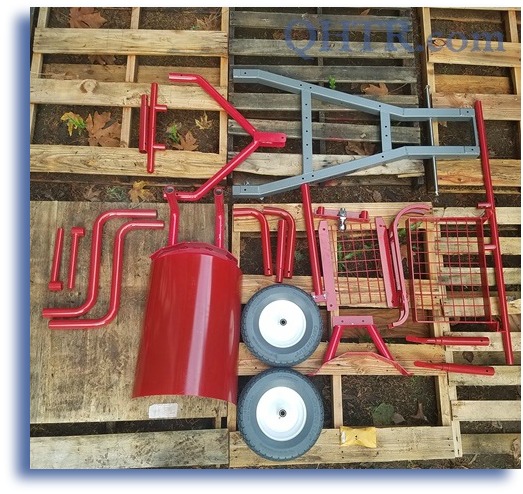

My first impression was from the drag marks across the dirt. I'm not complaining about the delivery person, I don't blame her at all. As I walked up to the three boxes and grabbed on to get them open, I could tell why they were dragged. These things were HEAVY! And after opening them and getting a good look at the WHaTS pieces, I could see why. This was some serious steel used to build this thing.

From Seth Mellinger, Head Engineer;

"The frame is constructed primarily from 2” A-36 steel square tubing (0.120” wall thickness) that is solid welded with multiple 0.406” diameter punched holes that will easily accept 3/8” diameter detent pins. Most attachments are made from 1-1/4” (1.66” O.D.) schedule 40 pipe and some are made from 1” (1.315” O.D.). With two wheels a WHaTS has a weight capacity of 800 lbs. and with three wheels this increases to ~1200lbs. It can handle some SERIOUS weight."

Even with the care taken to use several layers of plastic, bubble wrap, and even sheets of foam, the pieces did not survive the shipping process unscathed with all that steel shifting around.

But, the damage was only cosmetic so no real harm done.

Another minor flaw, and again, only cosmetic (you know a good tool when you have to point out cosmetics to find a negative), the finish from the factory showed some careless application. A simple enough fix but frankly, not bad enough to be a major concern.

Thank You, Your Likes Matter!

Let's See What This Workhorse Can Do!

Even without consulting the easy to follow video direction on the WHaTS website, I was able to quickly get the axle, wheels, "fender", and correct pieces assembled in order to put the system to it's first and most basic task... hauling a load of water containers down the muddy trail on the hill to my place to fill my tanks.

As simple as this job may seem, it actually shows perfectly the exact purpose of this very versatile tool;

I usually dread this task in the winter time, carrying 100lbs of water several times a week down a muddy trail in the rain has gotten mighty unpleasant over the years. And though Moby, the great white diesel whale is very capable in the muddy terrain, I don't want to turn the crude road down into a rutted mess.

Enter the WHaTS... I was able to load ~200lbs of water and haul it all with ease in only one trip, problem solved!

To say that the WHaTS eased my workload is an incredible understatment. Loading the water jugs onto the low deck of the WHaTS took little effort, the handles are positioned such that you don't have to even bend to grab them, and the walking space of the deck is so large that you are able to walk naturally without concern of banging your shins on anything. Just kneel a bit to grab the handles, straightening and lifting is easy with the low center of gravity balanced so well over the wheels and start walking. The flat-proof wheels rolled quite well over the uneven ground but I can see how they could be difficult to push through very soft, muddy ground.

I'd say the effort involved is ~10% of what it used to be.

Comparing to the closest "competitor" to the WHaTS, the wheel barrow, I would hate to even try.

Loading over the much higher sides would only hold two or three jugs, doubling my workload. And even with a two wheeled barrow, it would be much more unstable over the muddy, hilly terrain.

Again from Seth;

"Each flat-proof wheel has two heavy duty, sealed ball type bearings that accept the ¾” diameter stainless steel axle. The key features of the WHaTS design are its excellent load balancing, robust construction, low center of gravity, impressive leverage and load bearing capabilities, and the easy interchange between multiple applications without the need for tools."

Plywood and Panel Hauler

Construction is hard enough but when you are doing it yourself, it can really be tough.

Especially on your body. When it comes to hauling large loads like plywood, it's not so much the weight as the size that can make the load unwieldy and jack your back up quick.

Sure, when you're at the hardware store, the forklift makes a quick and easy job of loading all the lumber you need into your truck but when you get home, unloading it is another story.

After consulting the simple video directions just to confirm that I was using the proper components, I assembled the plywood hauler in about 60 seconds and rolled it over to the bed of Moby where I had a decent pile of OSB stacked. One by one I was able to just slide each panel down onto the waiting deck of the WHaTS without even having to lift a single one.

With the same ease as hauling the water, I rolled over to the conex where I was storing the lumber for my build and just slid them off the deck and into the conex, again without having to lift a single one.

MUCH easier than even having two people do the same job.

Conclusion... For Now

As our readers know, one strength of the reviews we do here at QHTR.com is the fact that we use tools in real world situations over several weeks to months to show you what you can actually expect over the lifetime of the tool.

As seen in the photo above, there are many configurations that Gerry and Seth sent for us to evaluate in addition to the Plywood and Panel Hauler, we have the...

- Firewood Hauler

- Lumber and Pole Transporter

- Wheeled Pry Bar

- Rock and Debris Hauler

- Trailer Ball and Mount

Seems we have a lot of work ahead.

While our preliminary view of the WHaTS is very positive so far, stay tuned as we really put it to work and show its varied uses listed above, and more!

More Quality Tools Reviewed For You!

Thank you for commenting on our page!

If you find anything useful on Quality-Handtool-Review.com, it sure would help out if you put a link in your blog, article, Facebook comment, etc.

Thank You!

Popular Reviews

Comments?

While we try to give you everything you need to make the right choice in investing in a tool, we may have missed the exact question you have.