Here Is All The Information You Need To Make That Purchase Of The Dremel 4000

The Dremel 4000 is Dremels

flagship rotary tool, with the highest and newest technology (In 2009. Superseded

by the 4200 in 2012 with the addition of the EZ Change system. You can convert any Dremel rotary tool with this.) to make your work easier and help you do more with

just one tool. Starting with humble beginnings as the Moto-Tool but

continuing as the innovative and diverse rotary tool that it is to this day,

the 4000 could prove to be one of the most useful tools in your

collection.

Every

Rotary tool attachment and accessory that is made will fit on this extremely

handy little tool including Multi-Saw and

Planer attachments for the 400 series XPR rotary tool. Some of the attachments that will make your life easier...

- 335-01 Plunge Router

- 225-01 Flex Shaft attachment

- 575 right angle attachment

- A577 detailers grip

- 1453 chain saw sharpener

- 679-02 Lawn Mower Blade, Chainsaw and Garden Tool Sharpener set

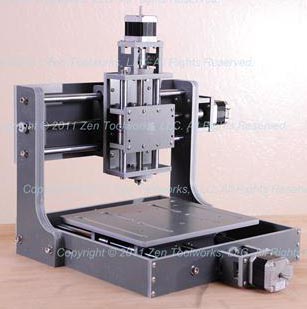

And so much more, and with the ability to build a Dremel CNC, this will be one of the most

useful tools you’ll ever buy.

Is This Tool For You?

While I've seen Dremels rotary tools used on the job site for things like polishing cable lugs before being installed, the line is targeted mostly for serious do-it-yourselfers or professional small grade like instrument making rather than professional construction/contractors

Grade:

-Worker/Contractor-

Here's The Kit I reviewed...

|

The 2/30 kit that I bought on Amazon came with the Dremel 4000 in a sturdy case that was designed to hold pretty much everything that you could need to use on your projects. Included is a handy little removable case that mounts securely into the main case pre-stocked with…

And even a small block of polishing compound Which is plenty to get you started. |

Photo by Mark Hinkle |

As you learn of more uses and need to start expanding your collection of accessories and parts, there is even room to store

- Extra collets and collet nuts (for larger mandrels)

- 4 Mandrels

- The collet wrench

- Several accessories

- The manual

- And even the 225 Flex Shaft attachment

What Is A Rotary Tool and What's It Do?

|

With a body made of high impact plastic like many of Dremels newer line of tools, a 1.6 amp motor, and easily replaceable brushes, the Dremel 4000 continues the company’s tradition of, usefulness. Although the durability has dropped drastically in the recent years. The variable speed range of 5000 – 35,000 rpm gives plenty of range for everything from low speed buffing to high speed grinding with room for some cutting in the middle. The speed dial is clearly marked with numbers corresponding to the actual speed and is up at the end of the tool so there is little danger of it accidentally being changed as you’re working. |

Photo by Mark Hinkle |

Like Most Dremel Tools. Usefel, Diverse

Here’s Where The High Tech Comes In

So, now we know that the Dremel 4000 can range from 5000 – 35,000 RPM for the various types of tasks we want to do. But what good does that do us when we begin our work and the motor immediately slows down due to normal friction? All those variable controls become a bit less of a useful feature. To address that, Dremel has come up with some nice tech to integrate into their top-of-the-line rotary tool. They have added circuitry for “electronic feedback for consistent power at lower and mid-range speeds”.

And, of course, with higher power and speeds comes more heat so a bigger cooling fan has been used. Be careful to not cover the ventilation opening with your hands when working.

If your Dremel 4000 is still heating up, you should check your brushes…

Plenty Of Pros, Here Are The Cons…

The biggest issue that I am seeing with the Dremel 4000 is with the motors. There have been many reports of them going bad and needing to be warranteed. Mine has had similar issues. At any speeds above 25,000 rpm, the motor starts to drag and fluctuate in speed. I'm sure that if I let it go like that it would just burn up. On a general positive note, Dremel is very good about setting you up for warranty return so you'll want to do that as soon as any problems comes up which leads to another issue...

I called to set up my return and then was too busy to get it sent. I wasn't too worried about it since I had a five year warranty period. Well, One of our readers, Brian recently sent a message asking about the warranty. Sure enough, after checking into it, I see that Dremel has dropped their warranty down to two years. I lose. I guess they are feeling the results of using what may be cheap Chinese crap in their tools.

It's really too bad, I hate seeing a good, American Company go down like this so I hate even writing this but the truth is the truth.

Looks like I'll have to do a write-up on Proxxon! : )>

|

One other thing that I

could see wrong with this tool was actually on the circle cutter/straight edge guide

attachment included. Where the locking screw tightened down for the adjustment,

the metal of the screw digs into the plastic. I can see that over time it will

likely chew up the housing until it is unusable. Weak plastic on friction parts

is something Dremel needs to do away with. A channel of metal secured into the

plastic as a base for the screw to secure to would solve that issue. |

Photo by Mark Hinkle |

Conclusion

While targeted more for the home do-it-yourselfer than the hard life of the professional, with

legendary Dremel innovation, a seemingly endless variety of bits, and a two year warranty along with

technology like electronic feedback control and the ability to use all

accessories and attachments, the Dremel 4000 brings the Moto-Tool to a new

level that can prove to be one of the most productive tools in your collection.

However, Dremel has taken

quite a beating in recent years for quality issues, mostly in their

motors. I can only hope that they get their act together and bump up quality, fast.

If you are considering buying the 4000 rotary tool for yourself or as a gift, you can use the link below but it's a gamble as to whether or not you'll get a good one. You may be better off going for a newer brand that is hungry for the rotary tool market and is making what looks like quality tools to prove it. Proxxon is a brand that I hope to be able to look at more closely, very soon and when I do, I will of course report back here to you.

Thank You, Your Likes Matter!!

Replaceable Motor Brushes Allow Years and Years of Service!

Most

utilitarian motors use carbon brushes and these brushes wear with use over time.

The carbon in the brushes is much softer than the commutator that they run

on which means they will wear down and not the commutator (that’s a good thing).

You can see that by changing the brushes, you can greatly extend the service

life of your tool. Amazon has them for a great price.

Dremel advises changing brushes every 60 hours of use or when there is 1/8” left on either brush. Always replace both brushes. And they have made the changing of brushes in the Dremel 4000 about as easy as it gets (this tutorial is for the U.S. model. Australian, U.K., Brazilian, etc. models must be disassembled to inspect/change and will NOT void your warranty). All you need is the small screwdriver that comes with your tool (it’s built into the end of the wrench).

|

1. Unscrew the brush cap (there are two) just below the variable speed control Photo by Mark Hinkle |

2. Grabbing

the small brass spring, pull the worn brush from the housing Photo by Mark Hinkle |

3. Place the new brush in the housing

4. Replace brush cap

5. Repeat for other side

6. Run for 5-10 minutes with no load to wear them in

Simple! And you just multiplied the life of your tool by a great amount.

BTW, you may notice that the brass spring was stretched out of round in the picture. That's nothing to worry about, as long as it fits in the housing fine.

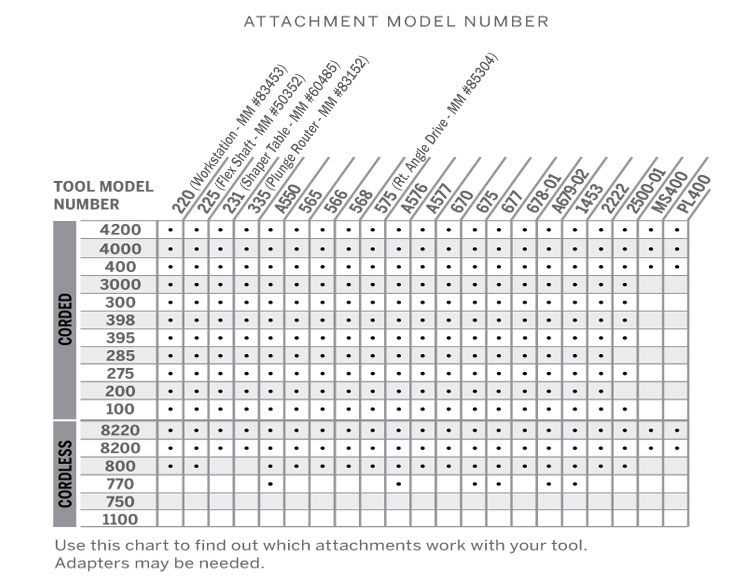

Will That Attachment Fit Your Tool? Here is a handy chart to tell you if an attachment will fit on your model of tool.

Have You Been Wondering What Bits Are available For Your Dremel 4000? Download a full chart on all the bits you'll need here. (PDF 1.25 meg)

Tip!

We show a very useful project below, but if you're looking for this and more Dremel tool projects click here!

Looking For A Dremel Tool Project? Use Your Dremel 4000 To Make Your Own Mini Table Saw/Router/Shaper!

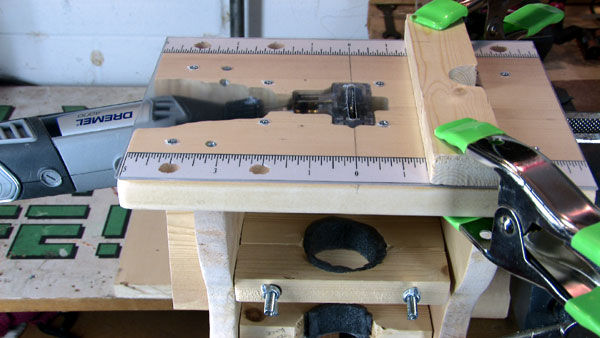

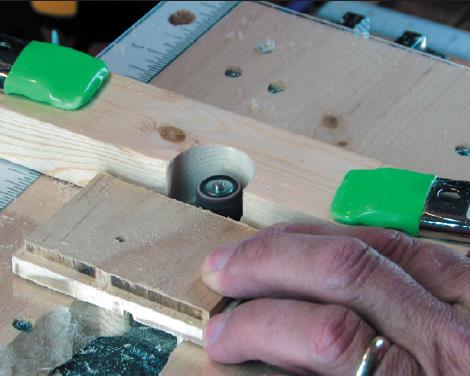

|

SDudley in Florida designed this very well thought out table that can be used as a Mini Table-Saw | |

|

|

|

|

Or a mini router table and shaper/sander |

Here is a video showing the assembly process. If you're interested in seeing the whole project, you can get it all here.

Top 20 Dremel 4000 Rotary Tool Attachments

(Also Fit The 400 XPR)

|

|

PL400

Planer |

|

|

|

|

|

Considered a must have for many. For the quickest bit changes. Never mess with collets again! |

|

|

|

|

|

|

|

678

Circle Cutter and Straight Edge Guide |

|

|

|

Here's Dremel, Beefing Up Their Product Line!

The main complaints that I’ve heard about the Dremel Product line in general stem from people using them beyond their design capabilities. In other words, they work them too hard, and the motors.

But, if Dremel is a smart company (and I believe that they are) they will start to design things that are more durable to rise up and meet the expectations and needs of their customers. After all, all that means is a better reputation and more sales.

Well, here is a good example of that. I have heard some people were unhappy with the thin, fiberglass reinforced cutoff wheels that Dremel offered in the past. One way to help that is to stack two wheels together (tip!) and that will get the job done but it costs twice as much because you’re wearing twice as many wheels out and your kerf will be twice as wide.

The New 506CU And EZ506CU Cubic Boron Nitride Super Cutting Wheel

To resolve this issue, Dremel has just introduced (March, 2014) a new, stronger cutting wheel, the 506CU and the EZ506CU (for the EZ lock) with an incomparable cutting grit called Cubic Boron Nitride. This new abrasive medium keeps the blade sharper longer, keeps it from heating up as much and is much stronger over all (according to their tests).

They claim that these new wheels will last AT LEAST 20 times as long as the old wheels in your Dremel 4000. Now that’s quite a claim and if true, is exactly the kind of thing that we are looking for here at Quality Handtool Review… an INVESTMENT. And a twenty time increase in production and money saved is just that.

Now, the cost is a bit steep for the initial purchase, but remember here at QHTR it's overall value that we are looking for and IF the claims of 20 times longer life are true, then the cost works out to about the same as their fiberglass reinforced wheels... about a buck a piece but you save the hassle of having to change wheels as often. AND the price is likely to drop over time.

One Customer Review Said...

"Finally Dremel has created a cutting disc that does not grind itself into nothing. I have had this wheel for a couple of months now, and it is nothing short of amazing when compared to other Dremel cutting wheels. I have used this to cut through rifle barrels, and it cuts through them without issue. If you do a lot of metal cutting with your Dremel, this is the wheel for you."

Update!

We were able to get some 506CUs in and give them a torture test.

One word… ‘Impressed’

In the video below, I show that what I’m cutting is 7 gauge steel (way outside its previous cutting range)

And here, I start cutting the steel and show how the wheel doesn’t shrink at all.

I think we have a winner here folks. Based on this quick test, this new cutting wheel shows me that with normal use, 20x the life of previous cutting disks is a very conservative estimate.

Buy these awesome, long lasting cut off wheels from Amazon here for the standard and here for the EZ lock.

And as with all new products, we'd like to hear your take on them. If you have used these, please go ahead and take some time to let us know what you found!

Check Out These Other Dremel Related Tools

|

|

|

Dremel is a registered trademark of the Robert Bosch Tool Corporation.

Tell Us Your Dremel 4000 Story Here!

What kind of experience have you had with the Dremel 4000?

What projects have you created with it? Tell us about any pros or cons that you have seen.

Thank you for commenting on our page!

If you find anything useful on Quality-Handtool-Review.com, it sure would help out if you put a link in your blog, article, Facebook comment, etc.

Thank You!

Quick Links

Attachment And Bit Charts

Does That Attachment Fit Your Tool? What Bits Are Avalable? Find Out Here

Dremel 4000 Manual (PDF)

Dremel 4000 Brush Replacement

(U.S. version only)

Popular Reviews

Comments?

While we try to give you everything you need to make the right choice in investing in a tool, we may have missed the exact question you have.